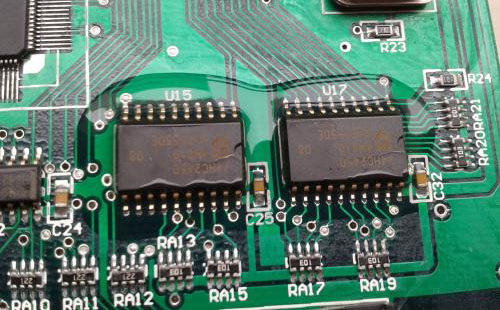

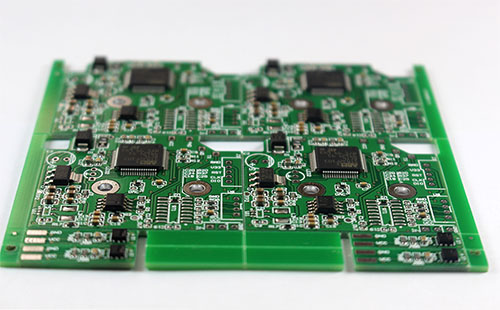

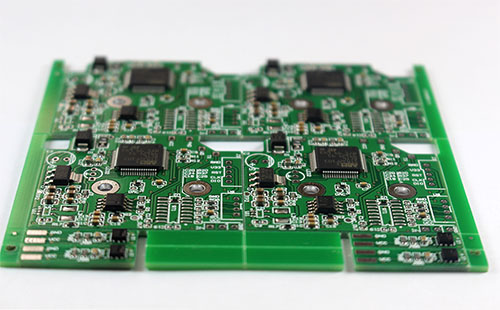

The circuit board is short circuited. How can I improve it?

circuit board short circuit is a problem that almost every circuit board manufacturer encounters every day, and such problems have been puzzling production and quality management personnel all the time. The problems caused by it, such as replenishment due to insuffICient shipment quantity, overdue delivery, and customer complaints, are more difficult for the industry to solve.

First, we summarize and classify the main causes of PCB open circuit into the following aspects:

Open circuit caused by exposed substrate:

1. The copper clad laminate is scratched before entering the warehouse;

2. The CCL is scratched in the process of cutting;

3. The copper clad plate was scratched by the drill bit during drilling;

4. The copper clad plate is scratched in the process of transportation;

5. The copper foil on the surface was damaged due to improper operation when stacking plates after copper deposition;

6. The copper foil on the surface of the production plate is scratched when passing the leveler.

Improvement method:

1. The IQC must carry out spot check on the CCL before entering the warehouse to check whether there is scratch on the board surface and the base material is exposed. If there is, contact the supplier in time and make appropriate treatment according to the actual situation.

2. The copper clad laminate was scratched during the blanking process, mainly due to the existence of hard and sharp objects on the table of the blanking machine. During blanking, the copper foil was scratched due to the friction between the copper clad laminate and the sharp objects. Therefore, the table must be carefully cleaned before blanking to ensure that the table is smooth and free of hard and sharp objects.

3. The copper clad laminate was scratched by the drill bit when drilling, mainly because the SPIndle clamp bit was worn, or there were sundries in the clamp bit was not cleaned, the PCB proofing drill bit was not firmly grasped, the drill bit did not reach the top, which was slightly longer than the set drill bit length, the lifting height during drilling was not enough, and the drill bit tip scratched the copper foil to form exposed substrate when the machine tool moved.

a. The clamping nozzle can be replaced by the number of times recorded by grabbing the tool or according to the wear degree of the clamping nozzle;

b. Clean the clamping nozzle regularly according to the operation procedures to ensure that there are no sundries in the clamping nozzle.

4. The plate is scratched during transportation:

a. During handling, the number of plates lifted by the handling personnel at one time is too much and the weight is too large. The plates are not lifted during handling, but pulLED up in the same way, causing friction between the plate corner and the plate surface and scratching the plate surface;

b. The boards were not placed neatly when they were put down, so they were pushed hard to rearrange them, which caused friction between boards and scratched the board surface.

5. Scratches caused by improper operation when stacking plates after copper plating and full plate electroplating:

When storing the plates after copper plating and electroplating, the plates are stacked together. When there are a certain number of plates, the weight is not SMAll. When the plates are put down again, the plate angle is downward and there is a gravitational acceleration, forming a strong impact force hitting the plate surface, causing the plate surface to scratch and expose the substrate.

6. The production plate is scratched when passing the leveler:

a. The baffle of the formwork machine sometimes touches the surface of the plate. The edge of the baffle is generally uneven and has sharp objects protruding. The plate surface is scratched when passing the plate;

B. The stainless steel transmission shaft is damaged into a pointed object, which scratches the copper surface and exposes the base material when passing through the plate.

The Circuit board manufacturer, circuit board designer and PCBA manufacturer explain how to improve the circuit board if it is short circuited.

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱